Yihao YH800 Series DRO

YH800-2: Full-function digital readout be used for all 2 axis machines (milling machine; boring machine; lathe machine; grinding machine.)

YH800-3: Full-function digital readout be used for all 3 axis machines (milling machine; boring machine; lathe machine; grinding machine; electronic spark machine; EDM cutting machine)

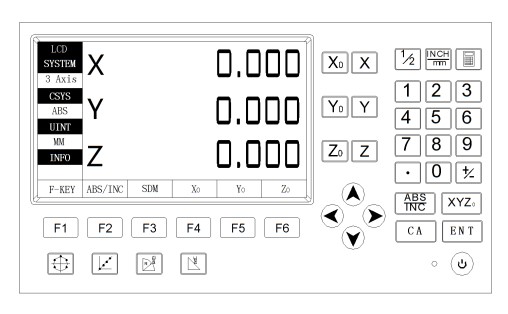

Description of Key Function For LCD DRO Digital Readout

YH800 LCD DRO MAIN FUNCTION | |

Zero selected axis. | Clearing

|

Clear all axes | Calculator |

Select axis to operate. | Function selection key |

Inch/Metric Switch | Process holes displayed equally on a circle. |

Center Finding | Process holes displayed equally on a line. |

ABS/IINC Switch | Simple R cutting function |

Numeric Key | Process a slope. |

Decimal Point | Stroll up or down to select. |

+/- Sign | LCD Screen switch key |

Enter | |

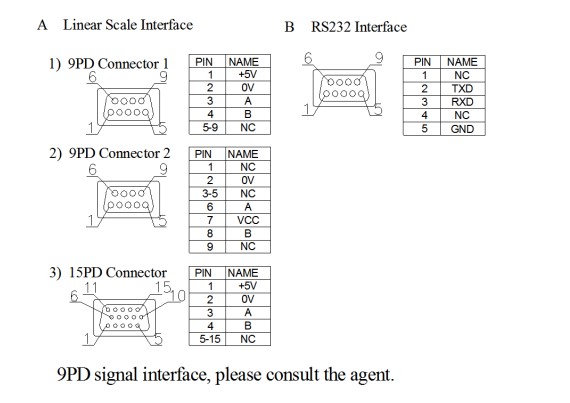

Interface

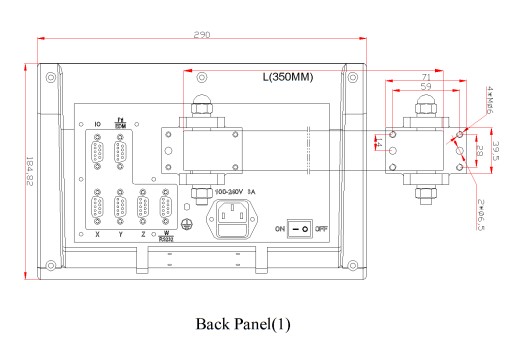

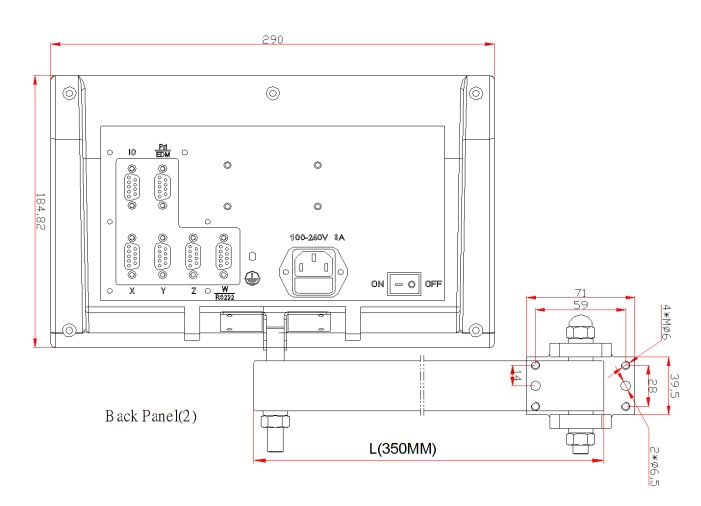

YH800 LCD DRO Digital Readout Dimension

TROUBLE SHOOTING

The following are the easy solvent for troubleshooting. If they can not work: please contact with distributor for more service.

Trouble | Possible Reason | Solvent |

No display | A B AC power voltage is not in the range of 100V to 240V C LCD screen is damaged | A Check the fuse is OK or not. Check the socket is loose. B Check the input power voltage is in the range of 100V to 240V. C Replace the LCD screen |

Cover is charged | A Poor grounding is float B Leakage of electricity | Check the lathe and DRO are well grounded. |

Display value is doubled | A Improper resolution B check lathe mode | A Set proper resolution. B Set lathe mode off. |

No counting | A Poor contact of scale B No scale signal output C Useless of counting function | Exchange scale and check again. |

Display value is in disorder | Memory is disorder | A Clear system. B Check compensation is proper. |

Erroneous counting | A Poor precision of lathe B Too fast run speed of the lathe C Proper scale precision D Improper resolution is set E Improper linear error compensation F Useless of scale | A Repair lathe. B Reduce the move speed of scale. C Reinstall scale. D Set proper resolution. E Set proper linear error compensation. F Repair or exchange linear scale. |